|

|

|

KAWAN ENGINEERING SDN. BHD, a professional welding fabricator for crude oil plants equipment to a technology driven equipment and steel maker in Malaysia in last 35years.

- ASME: "U" Stamped Pressure Vessels

- The National Board Stamp certified pressure vessel and welder.

- NBBI: "NB" Mark and Register Boilers

- ISO 9001:2008 Quality Management System

- DOSH: Departmental of Occupational Safety & Health Licensed Manufacturer

- Manufacturer of Unfired Pressure Vessels & Heat

Exchanger

- Manufacturer of Hot Water Boiler, Thermal Oil Heater

and Coiled Once-through Boiler

- Gas Contractor (Gas Piping)

A licensed to manufacture Heating Boilers and Unfired Pressure Vessels, Calorifier & Heat Exchangers by the Departmental of Occupational Safety & Health (DOSH) Malaysia. Accreditation by the American Society of Mechanical Engineers (ASME) as authorized "U" Stamp maker is also obtained. Pressure vessels are manufactured and tested by us in accordance with the A.S.M.E. Boiler and Pressure Vessel Code.

|

|

Materials

Kawan manufactures vessels and calorifiers with quality raw material manufacturers over Europe and Japan. Standard materials are 304/304L, 316/316L/316Ti, Incoloy 825, Nickel, Inconel, SMO 254, Titanium/Titanium-Pd, Hastelloy, Monel, Tantalum and others. Please consult our factory for special request.

Product Range

- Hot water storage tanks to DIN 4753

- Shell & Tube type heat exchangers

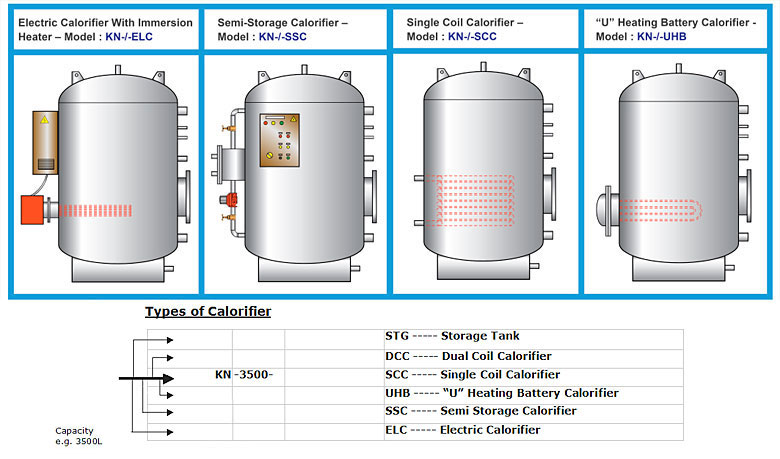

- Calorifier with "U" shape heating battery.

- Calorifier with Electric Heaters.

- Bare-tube heat exchangers

- Storage tanks for beverage industry

- Construction, computation and thermic design

- Shell & Tube Heat Exchangers

- Evaporators

- Spiral Pipe Heat Exchanger

- Half Pipe Vessels

- Jacketed & Agitated Vessels

- Finned Tube Heating Panels

|

|

Product Specification

- Stainless steel AISI316Ti or AISI 316L shell.

Other materials can be offered on request.

- Vented and unvented applications.

- Most advance MAG/TIG welding technique and treatment.

- Maximum Working Pressure up to 25Bar.

- Manufacturing to DIN 4753, BS853 and BS5500.

- Flange designed for international standard. E.g. DIN 2633,

ANSI B16.5 class 150, class 300, NPT, BS 4504, BS 21, BS 10 Table E,

EN 1092, ISO 2084, MSS SP 44, JIS, B 2210, NFE 29203, AWWA C207.

- Nozzle connections to adapt any type of heat exchanger and

heating elements. E.g. Plated type heat exchanger / heating coils /

shell and plate heat exchanger / "U" heating battery / electric heater

with control systems.

- Capacity from 200L to 15,000L

|

|

|

|

|